Energy Performance Analysis with KPI Dashboards

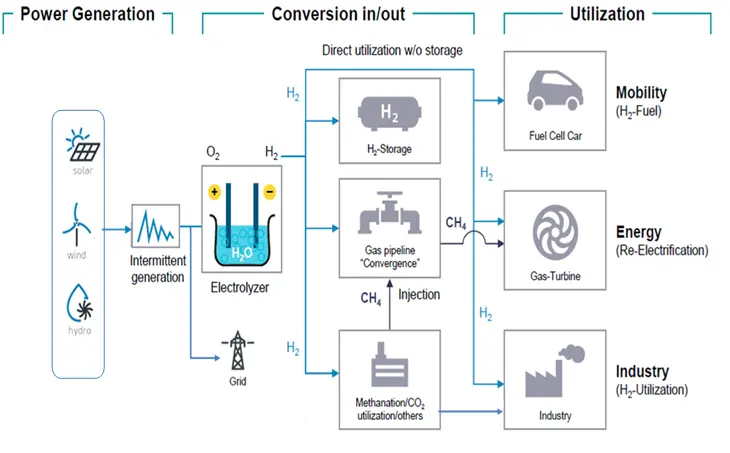

Solution helps to optimize hydrogen systems using real-time KPI dashboards and performance analytics to detect issues promptly.

- Real-time KPI dashboards shows performance predictions across H2 sub-systems e.g., electrolyzer, compressor & storage.

- Performance analytics reports on known threshold values for condition indicators that detects failure histories of similar assets.

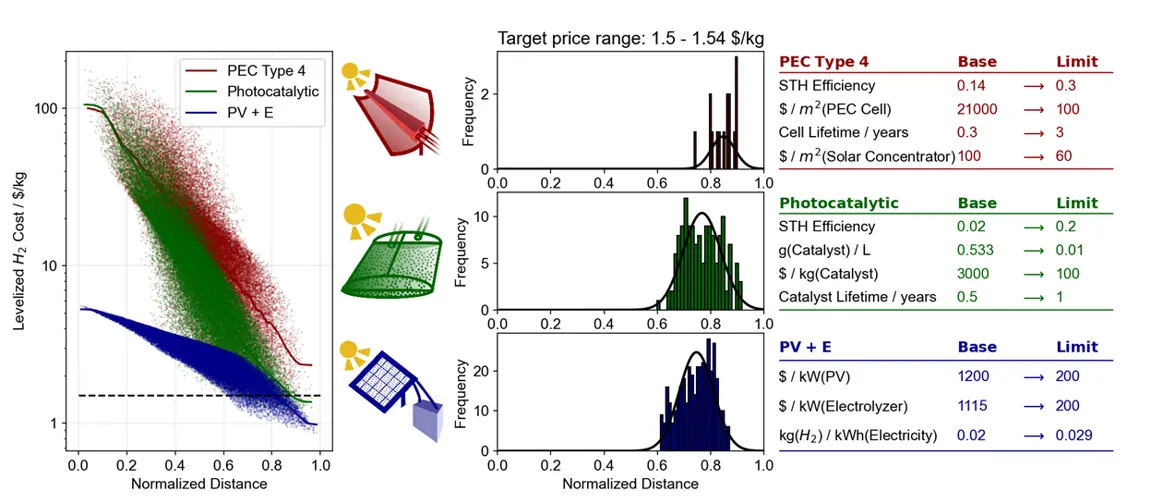

Production Cost Analysis with Forecasted Models

Solution use various models for production cost analysis, providing forecasts based on weather parameters and actionable plant-level analytics.

- Supports models such as physical (weather impacts), statistical (integrated moving averages), machine learning (random forest), & deep learning (neural networks).

- Production forecasts based on what-if models running on weather parameters and plant-level analytics for corrective action recommendations to maximize yields.

Production Process Analysis with What-If Simulations

Solution analyze production processes with configurable models, optimizing returns by considering factors like electrolyzer capacity, buffers, weather, and demand volatility.

- Support model configurations on multiple designs and scenarios on the production process.

- Considers electrolyzer capacity, to buffers (such as energy and hydrogen storage), and variables such as weather, demand volatility to maximize return on investment and minimize risk.